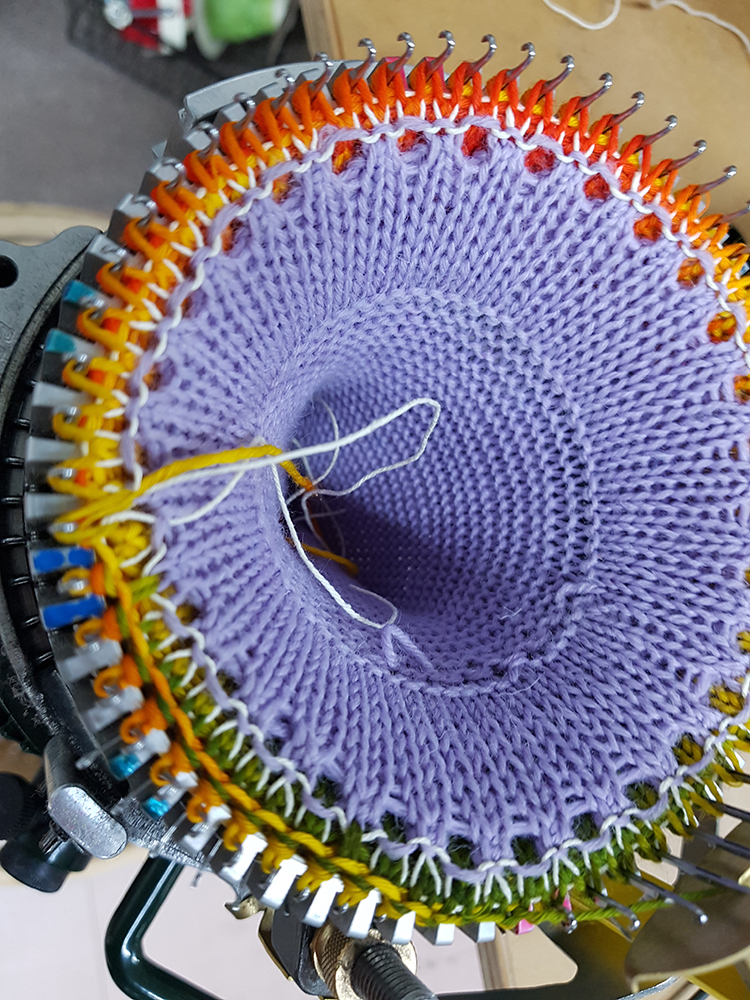

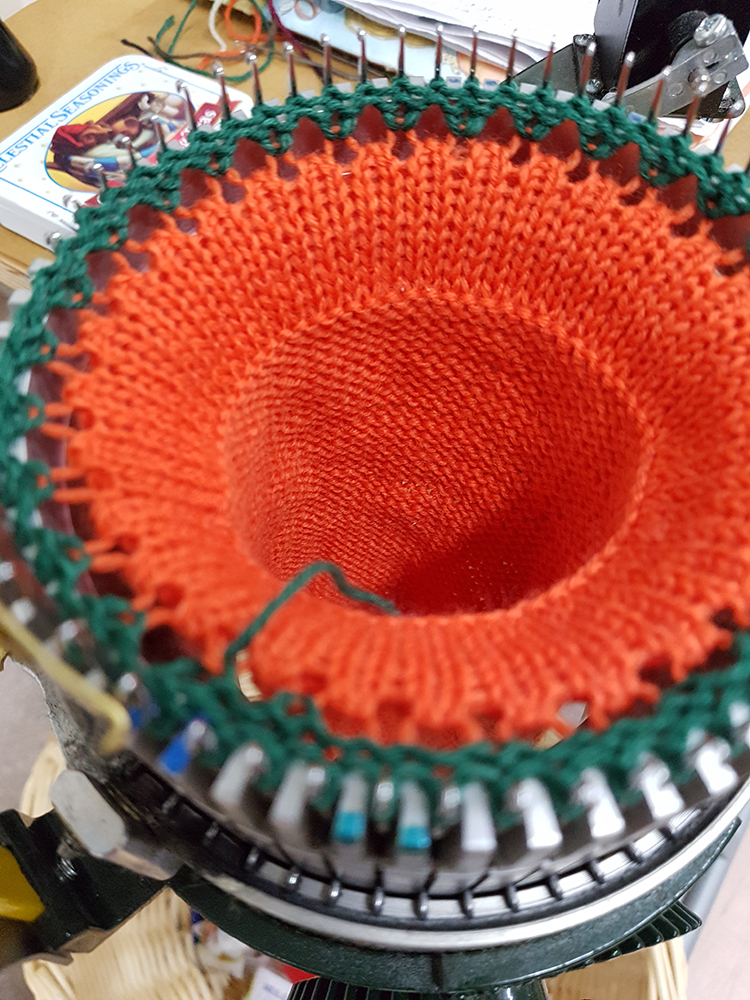

Wowzers! The store was incredibly busy this week. Between the sewing techs being here to service machines, Halloween coming up and the cooler weather inspiring more knitting projects, we definitely saw more folks this week. I assure you that I am celebrating that fact and not complaining. I’m so glad that I took the time to organize my leftover yarns right away. This is my Frankensocks week. My immediate inspiration was obviously Frankenstein’s Monster since I would be cobbling socks together using leftovers. However, as I was imagining my kids choosing which ones they want for Christmas, it occurred to me that it could also reference Frankincense and gift giving. So there we go! Two for one! I like it.

As the sewing work floods in, I have been very happy to keep the socks fairly simple this week. However, my Yarn Chicken exploits have simply continued from last week. There won’t be much of anything left in my bin when I’m all done. That’s excellent. That takes away any twinges of guilt I might have felt in expanding my stash again.

Despite keeping the socks simple, I had some mishaps.

I’ve been knitting each pair of socks and leaving them on the machine until the week’s worth are done, to close all the toes in the evening afterward. Because I had all those other socks attached to the machine, I was loath to start any socks over when things went sideways.

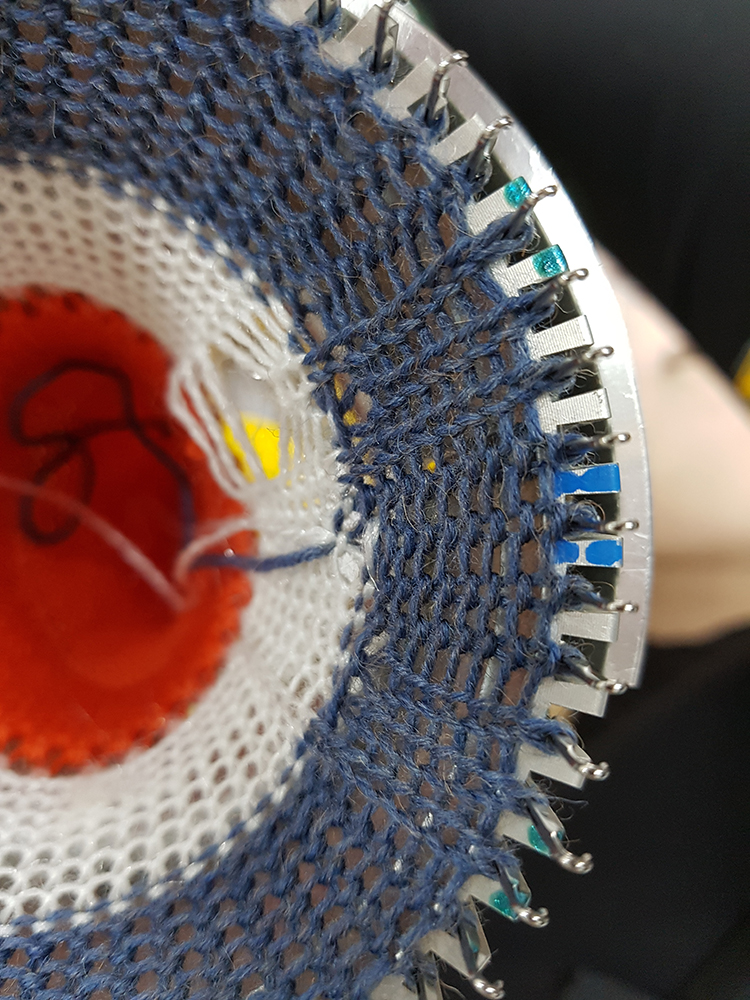

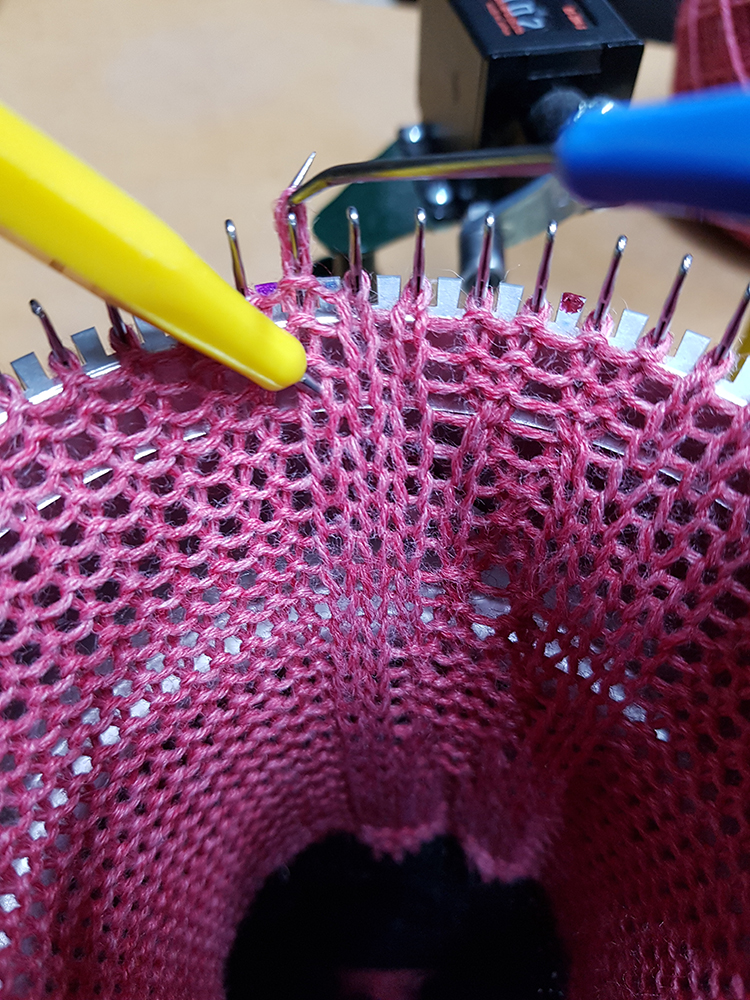

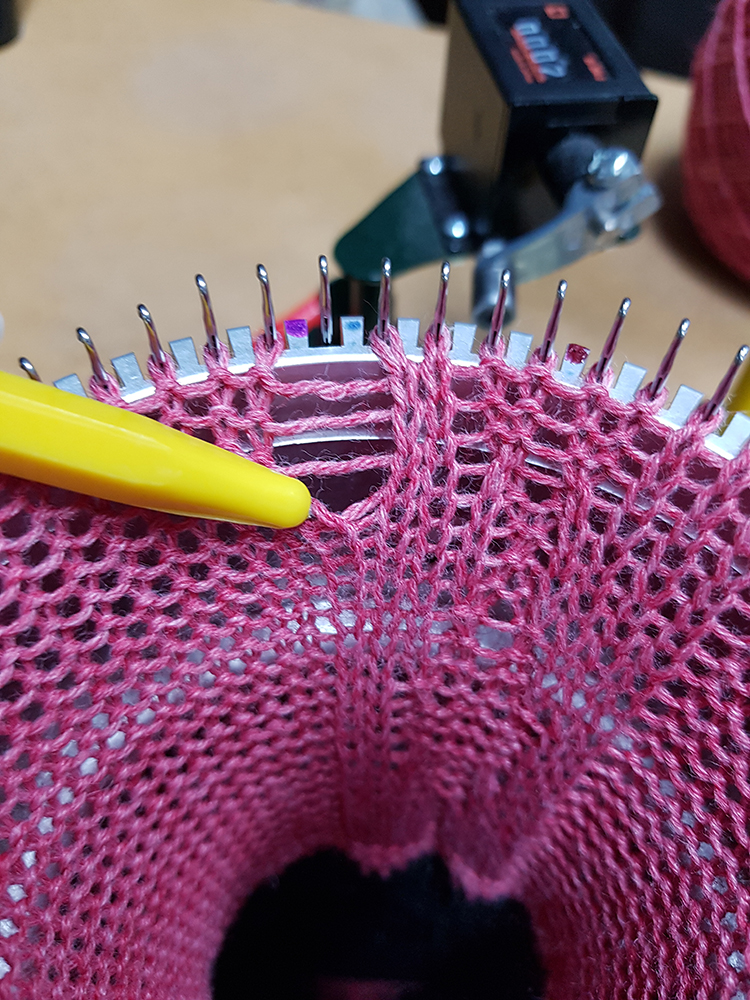

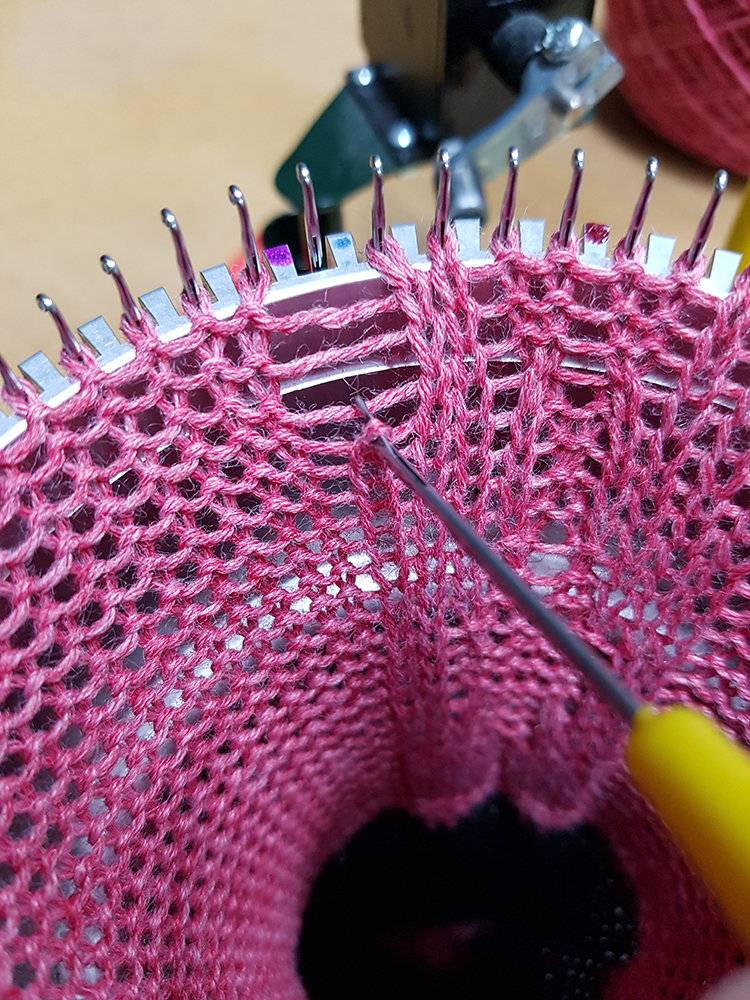

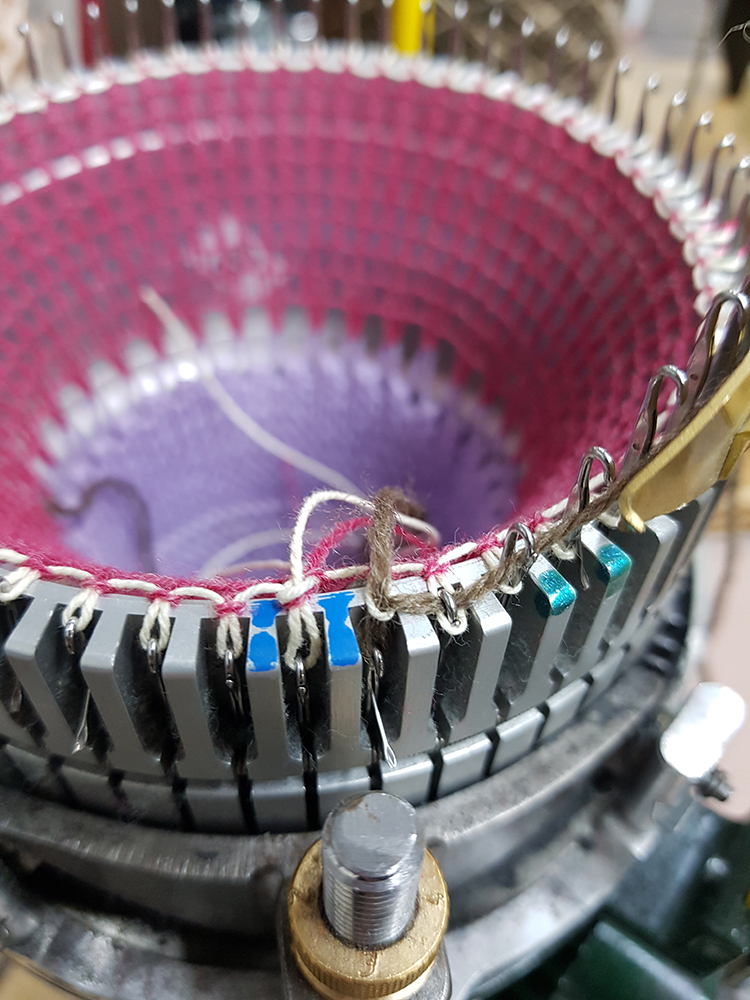

One of the stripey pairs of socks gave me some trouble. I finished the first sock just fine. In the second sock, when I switched from the first stripey yarn to the second one, I discovered that not only was there a knot, but they didn’t bother to make sure that the colour transitions were right when they tied the new section on. Ugh. The knot was messy and caused a bunch of stitches to drop. The combination of that and the wrong stripes just wasn’t what I wanted. I started to tink, but we’re talking about 8 rounds. Instead I dropped the whole sock off and unraveled the last batch of yarn. I took it back to the previous transition and rehung the stitches. Since I had marked the number of rounds when I switched yarns, I knew what to reset my counter to, thankfully. Good heavens! It took me about an hour to get it back on the correct needles and all the stitches knitted up to where they needed to be. Then I removed the offensive section of yarn from the ball so I could make my stripes match the first sock and finished the 20 or so rounds of the foot and the toe and knitted off the waste yarn. Unfortunately there was a twisted stitch or two that I didn’t notice until later. By that point, I simply didn’t care any more. I just left it.

That was painful! But I managed to get it all done. Hurray!

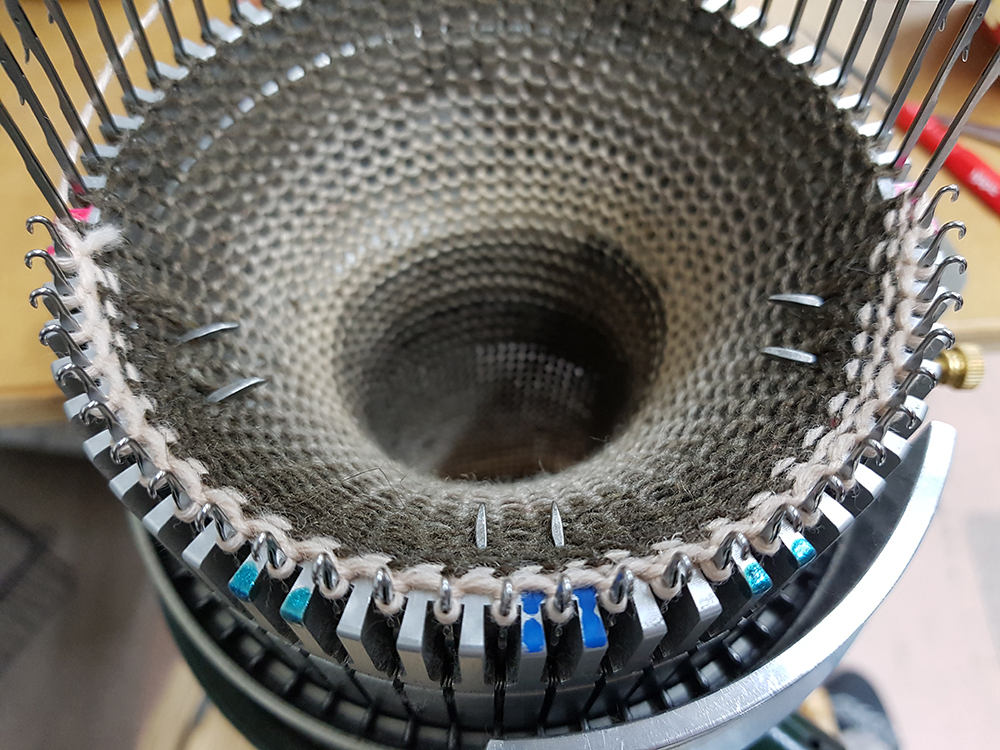

At the beginning of each pair of socks, I weighed each of the balls of yarn, of each of the colours, to determine which were the smaller ones respectively. I made the first sock using the smaller balls so I wouldn’t be as worried about running out on the second sock. I still ended up running out on the second half of the toe on one pair. Let’s face it. Those digital kitchen scales are great, but weighing yarn as you are removing yarn from the ball is a subtle operation. The weight changes by fractions of a gram as you go. With the balls weighing in at 12 or 13g, it may be unrealistic to think you can truly trust the scale to be accurate enough. So it’s close, but even thinking I was starting with the smaller ball, I had some surprises.

There was one issue that occurred a couple times that I thought I would mention. I was knitting along and found that suddenly the yarn felt really tight. It took a bit to realize that the yarn had hooked itself around one of the guides in the threading assembly. So words to the wise: if you feel resistance, be sure to stop right away and check the threading assembly to be sure that nothing has gone awry.

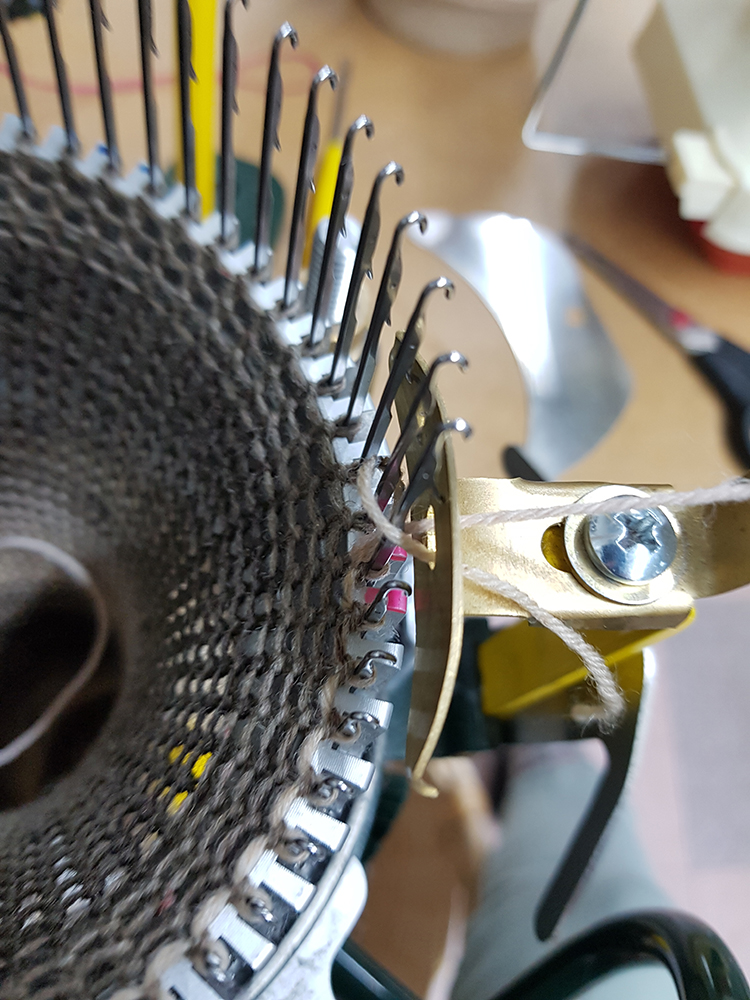

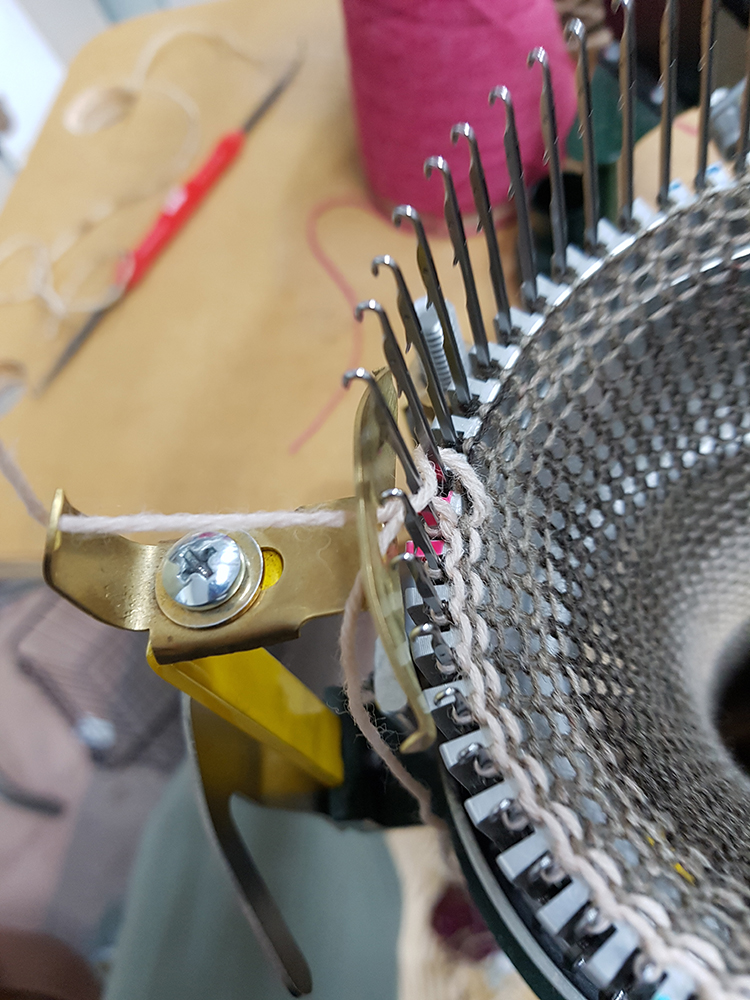

I ended up breaking the latch off one of the needles. It took about three rounds before I actually clued in as to what was happening. It was creating a lot of resistance because the yarn was accumulating loops (like a slip stitch to the back) behind the needle. I suspect that the latch broke because of how tight the yarn became when it was caught in the threading assembly. When I discovered the missing latch, I was able to simply replace the needle. I used the needle to latch up those three or four stitches and carried on.

I found a couple balls of yarn that were almost a full measure.

After two weeks of yarn chicken, it was so nice to just make the socks and not worry about how far I’d get before I would have to incorporate yet another colour of yarn.

It’s been really fun to see how the socks turned out these past two weeks. As much as there is a part of me that really likes the patterns in the yarn to match up on both socks, I really had to let go of that during this process. Because it was down to inches of extra yarn in some cases, I didn’t have the luxury of aligning everything to make them all matchy-matchy. But it turned out okay. It’s really obvious that I used the same yarns on each of the socks in each pair. Just because the patterns don’t match up exactly doesn’t mean that they don’t still look like they belong together. That was actually a lot of fun. It took away any pressure to make them perfect. That’s a good thing.